technology

HOME > technology

WORK 01Internal inspection

Radiographic Testing

IMPROVEMENT OF RADIOGRAPHY BY FCR

Low contrast indication on normal radiograph will be improved with FCR processing. These data will keep in optical disk and be stored easily.

We can make minimize the unavailable radiation at site.

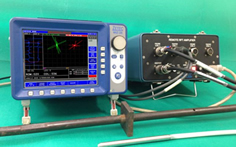

Ultrasonic Testing

Phased Array

Ultrasonic testing was remarkably improved after developed Phased Array technique (PA) by aperture synthesis method under continuous change for ultrasonic incident angle.Phased Array technique is realized significant improvement for recording of ultrasonic testing.

TOFD

TOFD method is useful to evaluate of entire cross-section for welds by using opposed two search units with a set and it’s moved continuously along to weld line.

Cost-effectiveness will be improved by shortening the working time and it will also give critical data, height of defects in thickness direction, for judgement of remaining life of subjects.

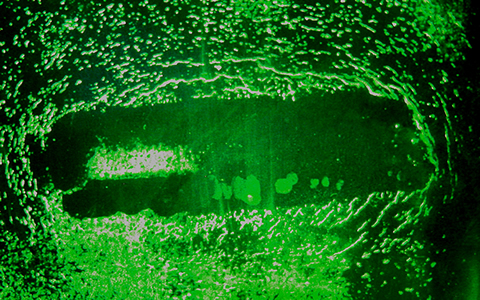

Internal rotary inspection system (IRIS)

TUBE THICKNESS GAUGING WITH IRIS SYSTEM

Continuous thickness measurement for Heat exchanger tubes will be performed with accuracy. Sectional drawing of tube wall can be seen on CRT and print out.

WORK 02External inspection

Visual Inspection

Visual inspection is a common method of quality management,data acquisition, and data analysis.

Liquid Penetrant Testing

Penetrant Testing (PT), is a widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials (metals, plastics, ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials, although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability.

Magnetic Particle Testing

MagneticTesting (MT) is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part.

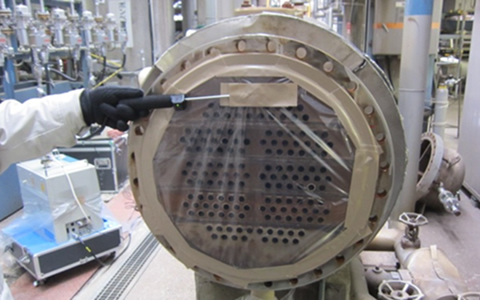

Eddy Current Testing

EDDY CURRENT TEST FOR NON-MAGNETIC METAL TUBES

We have long experience of Eddy Current test at site for non-magnetic metal tubes and store enough data in Oil refinery , Chemical , Power plants. and Ships.

WORK 03Special inspection

Scale Checker

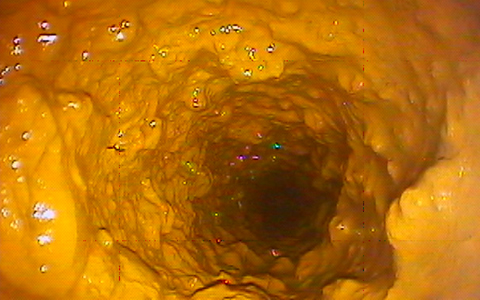

SCALE CHECKER SHOW PIPE CONDITION

Our developed easy handling SCALE CHECKER will inspect inside pipes without films. Choked condition & stuck rate of pipes can be shown quickly.

Remote field Eddy Current Testing

REMOTE FIELD EDDY CURRENT TEST (RFT) for STEEL TUBES

Remote field eddy current test has been possible to test Ferro-Magnetic metal tubes same as non-magnetic tubes.

We started earlier this testing and now got good estimation of clients

Leak Testing

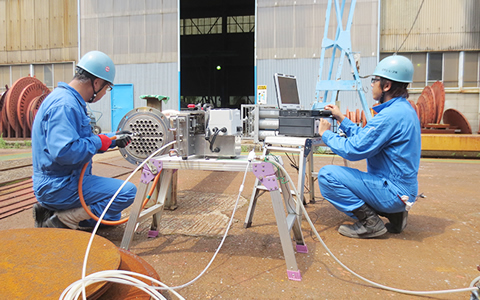

HELIUM LEAK TEST

Leak tests will be performed to confirm the safety and airtight of each vessel. We have enough experiences to evalvate the airtightness at site include it's planning and evaluation.

HELIUM LEAK TEST

Leak tests will be performed to confirm the safety and airtight of each vessel. We have enough experiences to evalvate the airtightness at site include it's planning and evaluation.

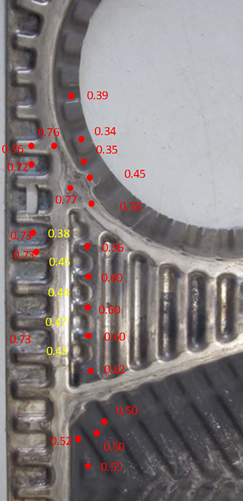

Development of Thickness Measuring System using Laser Sensor

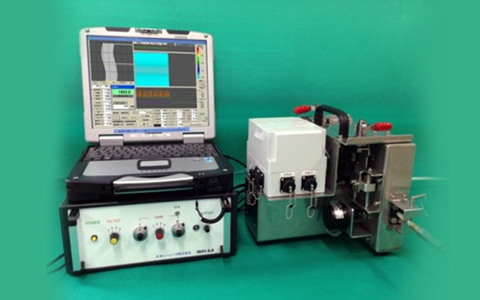

TUBE THICKNESS MEASUREMENT BY OPTICAL LASER

Determination of remaining tube's life installed in Heat exchanger has been done with extreme analysis on sampling tubes. We applied Optical Laser to measure wall thickness continuously.

The statistical calculation will be done automatically by PC.

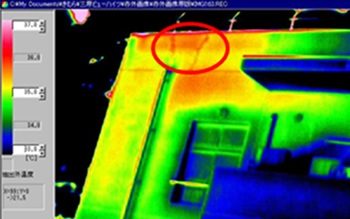

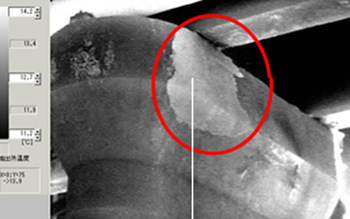

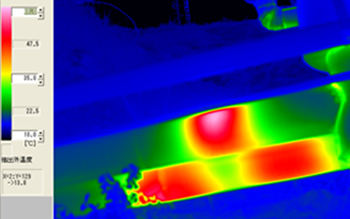

Thermography

ULTRA-RED VIEW INSPECTION BY THERMOVIEWER

We introduced high sensitive NIKON THERMOVIEWER for monitoring the operating condition of instruments and to find invisible damage hidden in concrete structures.

Broken concrete

Floating of concrete

Internal failure

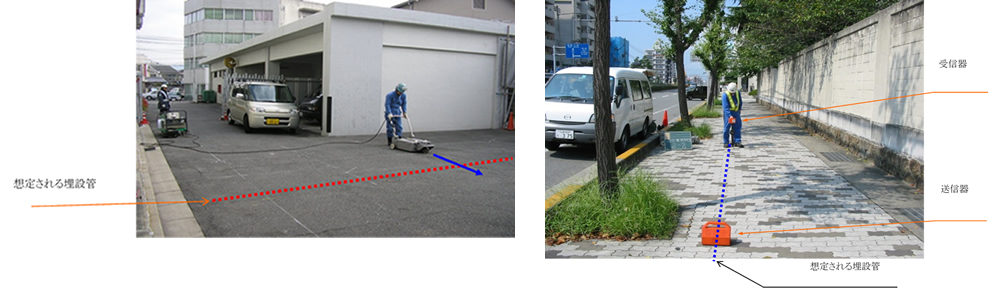

Ground Penetrating radar

UNDERGROUND INSPECTION BY PORTABLE RADAR

Portable Radar will find out invisible underground pipe line for maintenance and voids to keep safety driving on road.

APPLICATION

Reinforced bar detection in concrete walls by portable device.

Concrete building Structures Inspection

We started Concrete Structure inspection from 1990 and provided beneficial information for deterioration investigation for durability evaluation and reinforcement planning of concrete structures by joining each structure preservation project.

As past performance, elevated bridge for Shinkansen, road bridges, skyscraper and historic site of Atomic Bomb Dome in Hiroshima are listed.

Maintenance/Denelopment

"Maintenance works for infrastructure in use and industrial machinery is very important to evaluate the durability and safety in effective those use without accident.

The subject of maintenance works are Thermal Power plant, Petro-chemical plant, Water works & City gas facility, Road Bridge and Building etc.

We shall apply our own developed NDT technique, then our continuous developing effort is mandatory works. For achieving this duty, we are trying to collect of state-of-the-art technology for NDT and applying effective education and training for our employee.